When it comes to reliable and efficient snow blowers, Honda is a name that immediately comes to mind. But have you ever wondered where these impressive machines are actually made? In this article, we will uncover the fascinating origins of Honda snow blowers and delve into the locations where they are manufactured. So, sit back, relax, and prepare to embark on a journey to discover the birthplaces behind these winter warriors.

Manufacturing Locations

Japan

Japan is one of the key manufacturing locations for Honda snow blowers. The country boasts state-of-the-art facilities that adhere to Honda’s strict quality standards. With a long history of precision manufacturing and technological advancements, Japan is known for producing reliable and high-quality products.

United States

Honda also has manufacturing facilities for snow blowers in the United States. With a strong presence in the American market, having manufacturing operations in the U.S. enables Honda to cater to the local demand efficiently. This strategic decision ensures that customers in the United States have access to Honda snow blowers without any delays or import costs.

Other Countries

In addition to Japan and the United States, Honda has manufacturing operations in various other countries around the world. These locations play a crucial role in meeting the global demand for Honda snow blowers. By diversifying their manufacturing locations, Honda can minimize risks and cater to regional market needs more effectively.

Manufacturing Process

Design and Planning

The design and planning stage is where the foundation for Honda snow blowers is laid. This involves a meticulous process of research, analysis, and conceptualization. Honda’s team of engineers and designers work collaboratively to create innovative and efficient snow blowers that meet the needs of customers.

Parts Production

Once the design is finalized, the parts production phase begins. Honda manufactures a wide range of components for their snow blowers, including engines, frames, housings, augers, and impellers. Each component undergoes rigorous testing to ensure durability and performance.

Assembly

After the parts are produced, they are carefully assembled to create the final product. The assembly process involves bringing together the engine, frame, and other components to create a fully-functional snow blower. Skilled technicians follow precise procedures and use advanced equipment to ensure accurate assembly.

Quality Control

Quality control is a crucial step in the manufacturing process. Honda follows stringent quality control protocols to ensure that each snow blower meets their high standards. Initial inspection, performance and durability testing, and a final inspection are carried out to identify and rectify any potential issues.

Japan

Overview

Japan serves as the home and headquarters for Honda. The country’s manufacturing expertise and technological advancements make it an ideal location for producing Honda snow blowers. With a strong commitment to quality and precision, Japanese manufacturing facilities are renowned for their reliability.

Honda HQ in Japan

Honda’s headquarters in Japan is a hub of innovation and excellence. It houses the company’s research and development centers, where experts work tirelessly to enhance the performance and design of their products. The integration of cutting-edge technology and years of engineering experience ensures that Honda snow blowers are at the forefront of the industry.

Snow Blower Manufacturing in Japan

Japan’s manufacturing facilities play a significant role in producing Honda snow blowers. They are equipped with advanced machinery and follow strict quality control processes. Skilled technicians carefully assemble the components to create snow blowers that are renowned for their durability and efficiency. The snow blowers manufactured in Japan are not only highly reliable but also designed to tackle various snow conditions.

United States

Overview

The United States is a key market for Honda, and the company has established manufacturing facilities in the country to cater to local demand. By having manufacturing operations in the U.S., Honda ensures that customers in the region have easy access to their snow blowers.

Honda’s U.S. Headquarters

Honda’s U.S. headquarters in Torrance, California, serves as the nerve center for their North American operations. It houses a variety of functions, including sales, marketing, research, and development. With a strong presence in the American market, Honda’s U.S. headquarters contribute to the success of their snow blower manufacturing operations.

Snow Blower Manufacturing in the U.S.

Honda’s manufacturing facilities in the United States are known for their adherence to Honda’s strict quality standards. The facilities are equipped with advanced machinery and employ skilled workers who meticulously assemble each snow blower. By manufacturing snow blowers locally, Honda can efficiently serve the diverse needs of American customers and ensure fast delivery times.

Other Countries

Overview

Apart from Japan and the United States, Honda has manufacturing facilities in various other countries worldwide. This global presence allows Honda to cater to the specific needs and demands of different regions efficiently. By manufacturing snow blowers in multiple locations, Honda minimizes transportation costs and time, ensuring their products are readily available to customers worldwide.

Honda’s Global Presence

Honda’s global presence is a testament to their commitment to serving customers across the globe. With manufacturing facilities strategically located in different countries, Honda can adapt to market demands and cater to unique requirements. This global manufacturing network enables Honda to remain agile and responsive in today’s fast-paced business environment.

Snow Blower Manufacturing in Other Countries

Honda’s manufacturing facilities in other countries follow the same high standards and processes as those in Japan and the United States. These facilities employ skilled workers and use advanced technology to produce snow blowers that meet Honda’s stringent quality requirements. The snow blowers manufactured in these locations are tailored to suit the specific needs of their respective regions, ensuring optimal performance in various snow conditions.

Design and Planning

Research and Development

Research and development are the foundation of Honda’s innovative snow blower designs. Honda invests heavily in R&D to develop cutting-edge technologies and enhance the performance of their products continually. By staying at the forefront of industry advancements, Honda can offer snow blowers that provide superior performance and reliability.

Conceptualization

During the conceptualization phase, Honda’s team of engineers and designers brainstorm ideas and explore different possibilities. They consider factors such as usability, efficiency, and safety to ensure that the snow blowers meet the needs of customers effectively. This collaborative process allows Honda to create designs that are both practical and aesthetically pleasing.

Prototyping

Once the design concepts are finalized, Honda creates prototypes to test and refine their ideas. Prototyping allows Honda to identify any design flaws or areas for improvement. Through multiple iterations and rigorous testing, Honda ensures that each aspect of their snow blowers is optimized for performance and durability.

Parts Production

Engines

Honda snow blowers are equipped with high-quality engines that are manufactured to meet the company’s stringent standards. Honda’s in-house engine production facilities ensure that each engine is built to deliver optimal power, fuel efficiency, and reliability. Thorough testing and quality control measures are incorporated during the engine production process to guarantee peak performance.

Frames and Housings

The frames and housings of Honda snow blowers are manufactured to withstand harsh winter conditions. Using advanced materials and engineering techniques, Honda produces frames and housings that are lightweight yet durable. By maintaining a balance between strength and weight, Honda snow blowers are easy to maneuver while maintaining structural integrity.

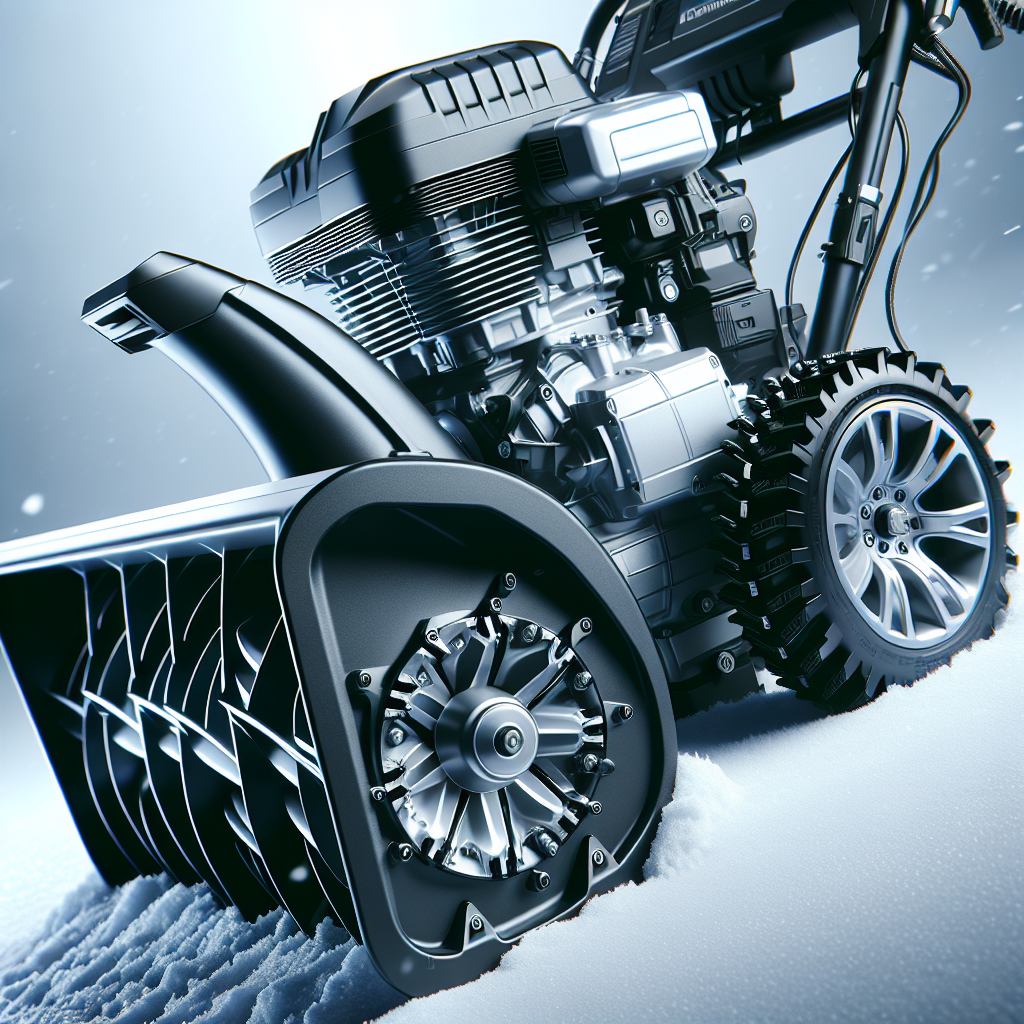

Augers and Impellers

The augers and impellers of Honda snow blowers are meticulously designed and manufactured to efficiently move snow. Honda utilizes innovative engineering techniques to enhance performance while minimizing the risk of clogs and icing. By focusing on the precise integration of augers and impellers, Honda snow blowers deliver exceptional snow clearing ability.

Assembly

Engine Assembly

The engine assembly process involves skilled technicians meticulously combining various components to create the heart of every Honda snow blower. Through precise assembly techniques and rigorous quality control, Honda ensures that each engine meets the highest standards of reliability and performance. A combination of automated and manual processes is used to guarantee accuracy and consistency in every engine.

Frame Assembly

The frame assembly is a critical stage where the structural integrity of the snow blower is created. Skilled assemblers use advanced tools and equipment to align and secure the frame components accurately. Honda places great emphasis on achieving precision during this stage, as any misalignment or structural weakness could affect the overall performance and durability of the snow blower.

Component Integration

Once the engine and frame are assembled, various other components such as augers, impellers, and controls are integrated into the snow blower. Skilled technicians ensure that each component is installed correctly, and all connections are secure. Thorough quality control checks are carried out to verify that the snow blower is assembled according to Honda’s standards.

Quality Control

Initial Inspection

At every stage of the manufacturing process, Honda conducts comprehensive initial inspections to guarantee quality and consistency. These inspections cover various aspects, including dimensional accuracy, component integrity, and adherence to design specifications. Through meticulous checks and tests, Honda ensures that any deviations or defects are identified and addressed promptly.

Performance and Durability Testing

Before a snow blower leaves the assembly line, it undergoes rigorous performance and durability testing. Honda simulates various real-world snow conditions to evaluate the snow blower’s performance and endurance. These tests assess the snow blower’s ability to clear snow efficiently, starting reliability, fuel efficiency, and overall durability.

Final Inspection and Packaging

Once all the quality control checks and tests are complete, each snow blower goes through a final inspection. Skilled inspectors thoroughly examine the snow blower to ensure that it meets Honda’s strict quality standards. After passing the final inspection, the snow blowers are carefully packaged to protect them during transportation and storage. Honda pays great attention to packaging to ensure that the snow blowers reach customers in pristine condition.

Packaging and Shipping Procedures

Product Packaging

Honda understands the importance of ensuring that their snow blowers are packaged securely to protect them during transit. Each snow blower is packaged using robust materials that provide adequate cushioning and protection against any potential damage. Honda’s packaging design also maximizes efficiency, enabling more snow blowers to be shipped in a cost-effective manner.

Shipping and Distribution Networks

Honda has a well-established shipping and distribution network in place to efficiently deliver their snow blowers to customers worldwide. Leveraging their global manufacturing presence, Honda strategically ships snow blowers from the nearest manufacturing location to minimize transit times and costs. By coordinating closely with logistics partners, Honda ensures that customers receive their snow blowers in a timely manner.

In conclusion, Honda snow blowers are manufactured in Japan, the United States, and other countries around the world to meet the global demand. The manufacturing process includes design and planning, parts production, assembly, and quality control. Each manufacturing location plays a crucial role in meeting specific market needs, and Honda’s commitment to excellence is evident in their meticulous approach to every stage of the manufacturing process. Whether it’s the innovative designs crafted in Japan, the efficient production in the United States, or the global presence in other countries, Honda’s manufacturing locations ensure that customers can rely on their snow blowers to tackle any winter weather conditions.